http://dx.doi.org/10.5991/OPF.2015.41.00XX

William Stowe is CEO and general manager of Des Moines Water Works (www.dmww.com), Des Moines, Iowa. Doug Oscarson is the utility’s energy manager. Rod Elsworth is president and CEO of Motors@Work (www.motorsatwork.com), Greenville, S.C.

Pumping Optimization

Delivers Big Savings

To improve its operations and financial performance, Des Moines Water Works has made energy efficiency a cornerstone of its operating strategy. Most of the utility’s energy management gains have been realized by optimizing its pumping systems. BY WILLIAM STOWE, DOUG OSCARSON, AND ROD ELSWORTH

IT WASN’T LONG ago that Des Moines Water Works (DMWW) staff believed the cost of energy was just part of doing business, to be embedded in the price of delivering safe drinking water and passed along to the customer. Now, faced with constrained revenues and increasing costs, DMWW is taking a hard look at ways

to increase revenues and reduce expenses. One way to address the realities of today’s economic outlook is to optimize energy consumption.

COST CONSIDERATIONS

Water treatment and distribution is an energy-intensive operation. In 2014, DMWW consumed more than 45,000

megawatt hours at a

cost exceeding $2.5 million. Considering that more than 80 percent of the electricity used by DMWW is for pumping, most of the utility’s potential energy management gains can be realized by operating the right (most efficient available) pumping system(s) at the right time, for the right duration, to meet operational requirements at the least cost.

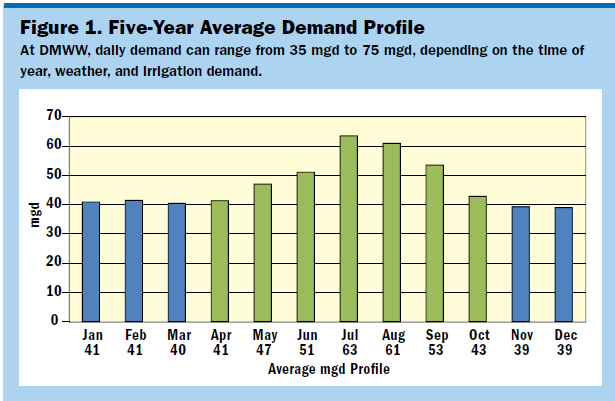

Like most water treatment and distribution systems, DMWW has pumping system redundancy to satisfy operational availability and varying capacity requirements. At DMWW, daily demand can vary by more than 200 percent, depending on the time of year, weather, and irrigation demand (Figure 1).